Product Showcase

PRODUCT NAME

Hydraulic Oil Cylinder

The hydraulic oil cylinder supports comprehensive customization from specifications to functional scenarios, offering selection design and localized service support.

PRODUCT NAME

Hydraulic Pump Station

The hydraulic pump station supports full customization from specification parameters to functional scenarios, providing dedicated power solutions for equipment to achieve efficient and stable operation.

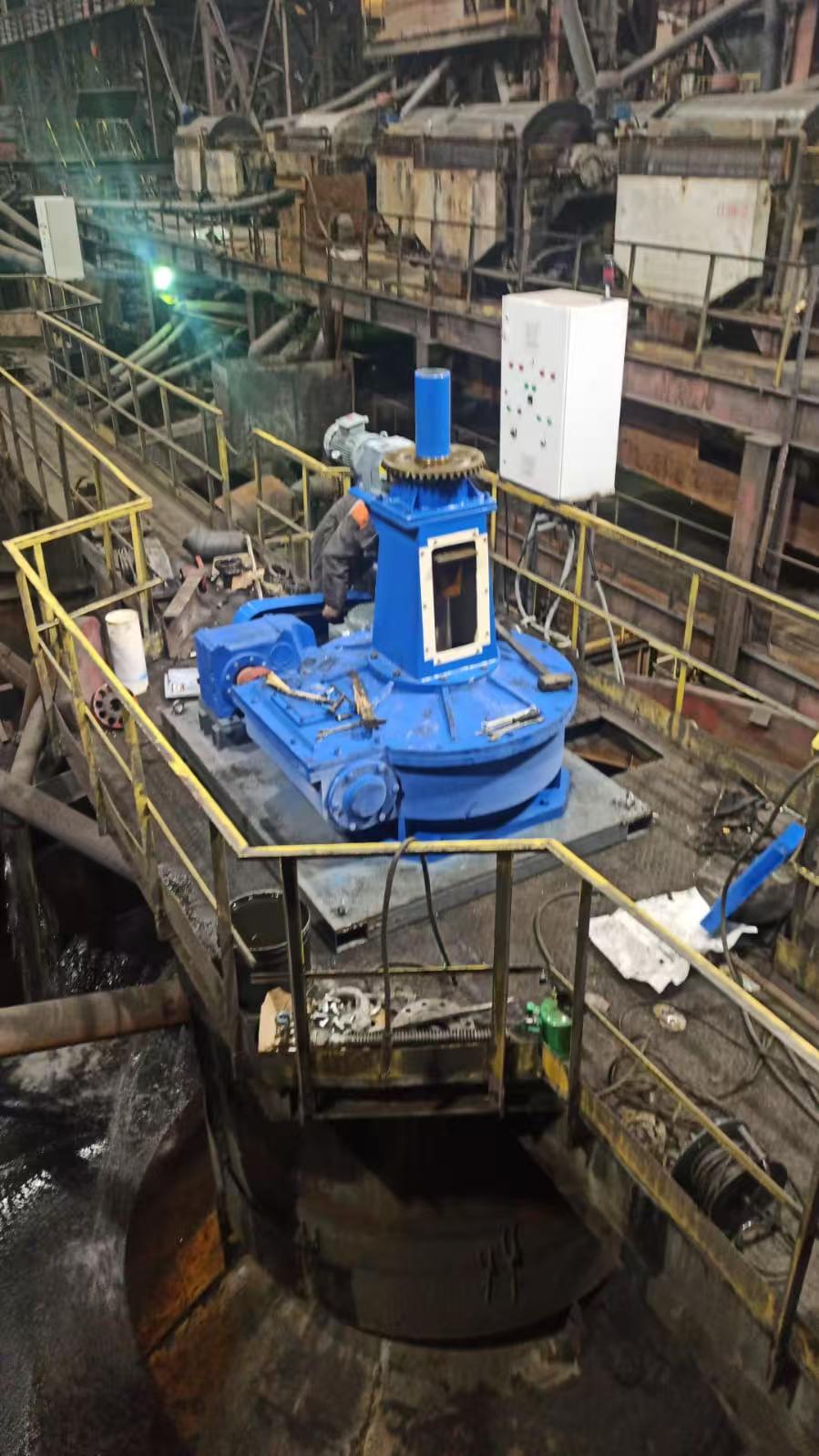

PRODUCT NAME

Dredger Reducer

Dredger reducers support non-standard customization covering JWZ series models, suitable for chemical, mining, and sewage treatment scenarios. Adjustable materials, dimensions, and performance parameters meet special working condition requirements.

PRODUCT NAME

Screw Jack

The screw jack supports non-standard customization of load capacity, structure, material, and functionality to meet personalized transmission needs.

PRODUCT NAME

Worm Gear Reducer

The worm gear reducer's customization capability enables flexible adaptation to diverse industry needs, enhancing overall equipment performance and applicability.

PRODUCT NAME

Bevel Gear Rotary Divider

Designed for diverse industrial scenarios, including special installation forms and load-bearing requirements for mechanical equipment. Modular structure design facilitates component replacement, reducing maintenance costs and downtime.

Dezhou Jingtong Machinery Manufacturing Co., Ltd.

Dezhou Jingtong Machinery Manufacturing Co., Ltd. specializes in R&D and production of worm gear reducers, screw jacks, worm screw jacks, ball screw jacks, spiral screw jacks, planar double enveloping reducers, soft/hard-faced gear reducers, and customized non-standard reducer solutions for import localization. We also process non-ferrous metal castings and serve as a Shandong non-ferrous metal casting base. Equipped with complete R&D, production, sales, and technical service capabilities, we possess advanced processing centers. Our products feature exquisite craftsmanship, backed by strong technical expertise, advanced processes, and comprehensive testing. With complete specifications, competitive pricing, contract compliance, and after-sales support, we undertake special reducer design/manufacturing and provide innovative transmission solutions for modernization.

We uphold integrity, credibility, and century-enterprise principles, prioritizing customers through effective cooperation. In today's competitive market, success hinges not just on price but technical support, after-sales service, and strict quality control. Jingtong Machinery will continuously improve management, training, product development, sales, and after-sales service, maintaining our ethos of integrity, dedication, and innovation to establish new quality benchmarks and become an industry leader.

We serve clients with premium products, attentive service, and supreme credibility!

Certifications & Honors