Product Navigation

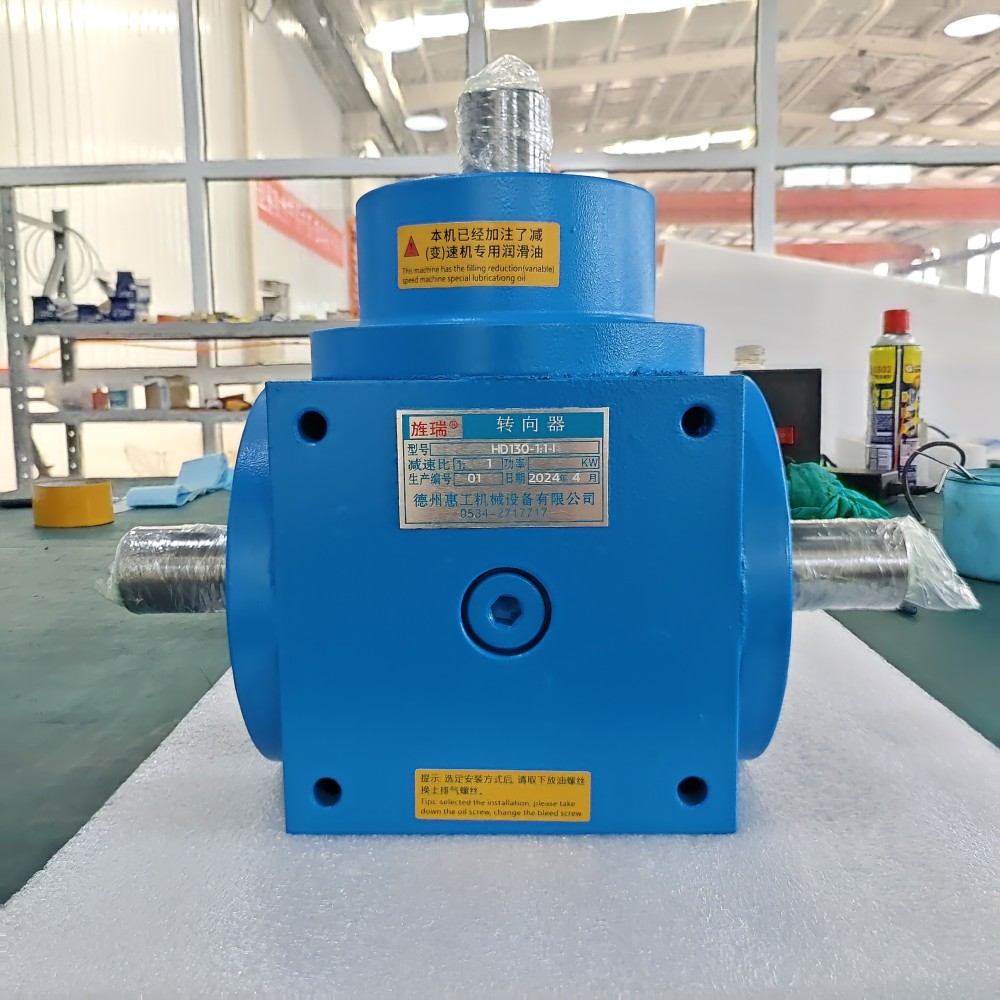

Non-standard worm gear speed reducers are deceleration devices designed based on specific application needs, achieving power deceleration and transmission through the meshing of worm gears and worms. Their fundamental principles are the same as standard worm gear speed reducers, converting high-speed, low-torque motor output into low-speed, high-torque output.

Non-standard worm gear speed reducers refer to worm gear speed reducers designed and manufactured according to specific requirements. Compared to standard speed reducers, non-standard speed reducers offer higher customization and flexibility in parameters, performance, and structure.

Definition and Basic Principles

Non-standard worm gear speed reducers are deceleration devices designed based on specific application needs, achieving power deceleration and transmission through the meshing of worm gears and worms. Their fundamental principles are the same as standard worm gear speed reducers, converting high-speed, low-torque motor output into low-speed, high-torque output.

Features

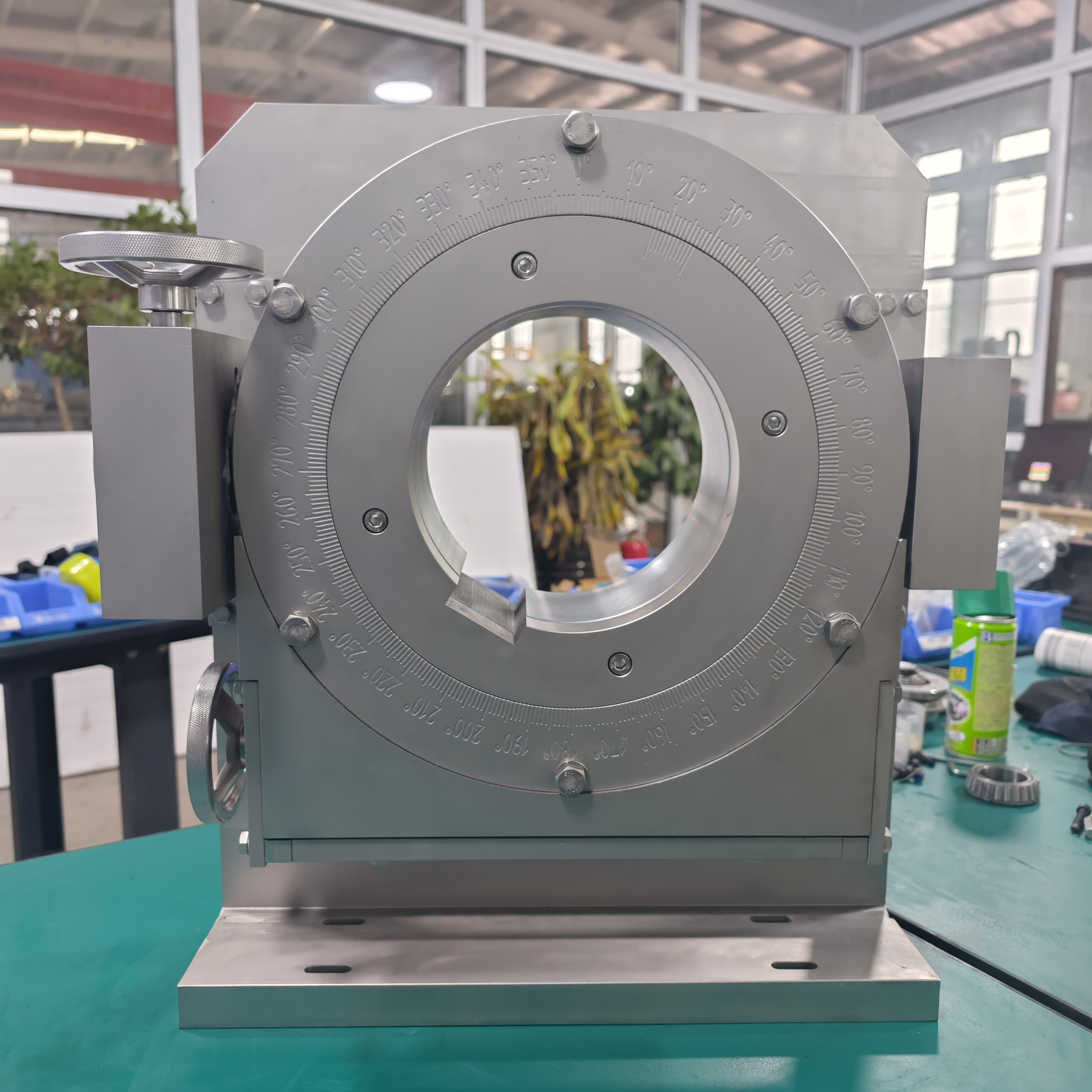

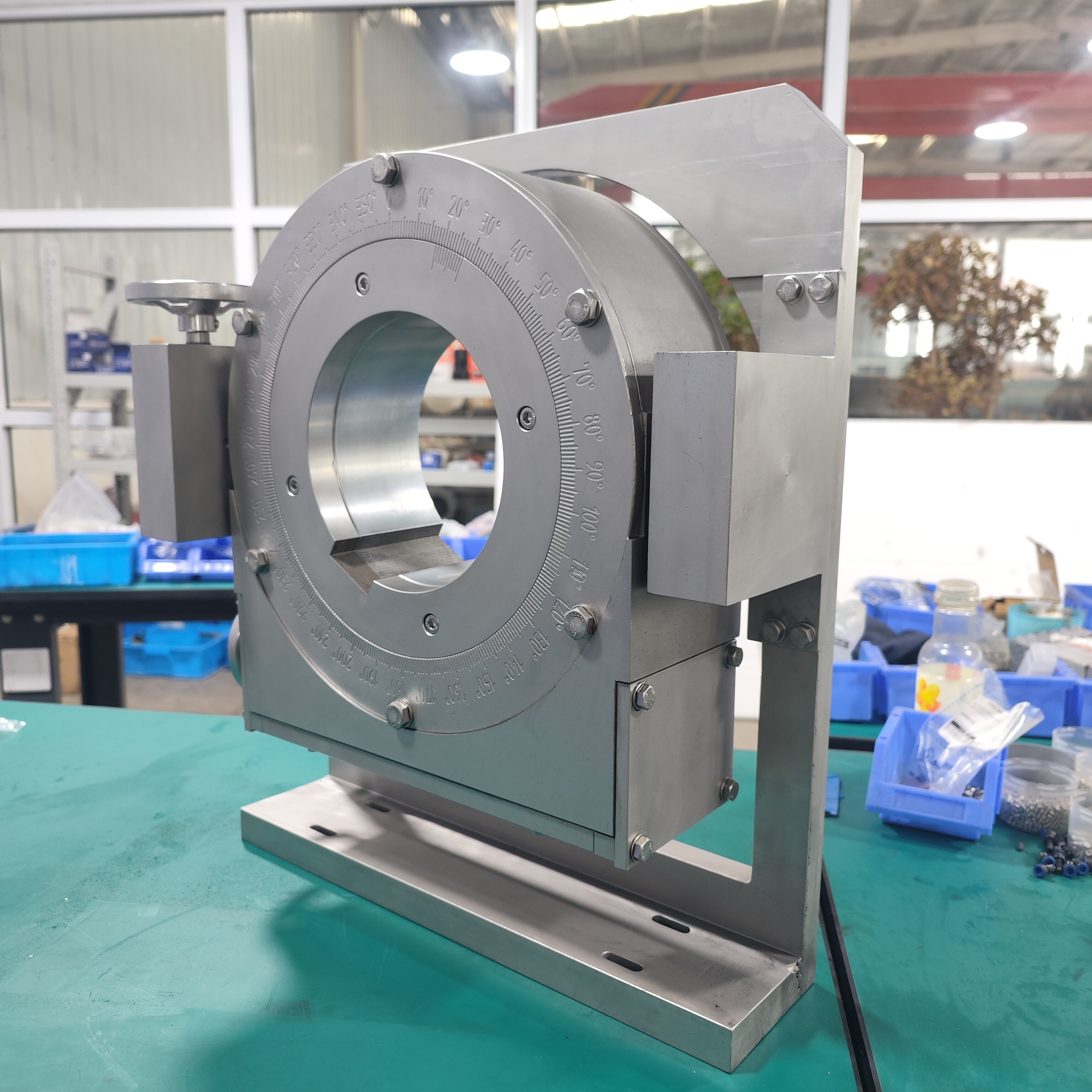

High Customization : Non-standard speed reducers can be designed according to specific application requirements, meeting specific speed, torque, and installation needs.

Flexible Parameter Settings : They can provide a wider range of reduction ratios, typically from 1:10 to 1:100 or even higher

Self-Locking Function : The worm can only drive the worm gear to rotate, while the worm gear cannot drive the worm in reverse. This feature is particularly useful in equipment requiring anti-reverse rotation.

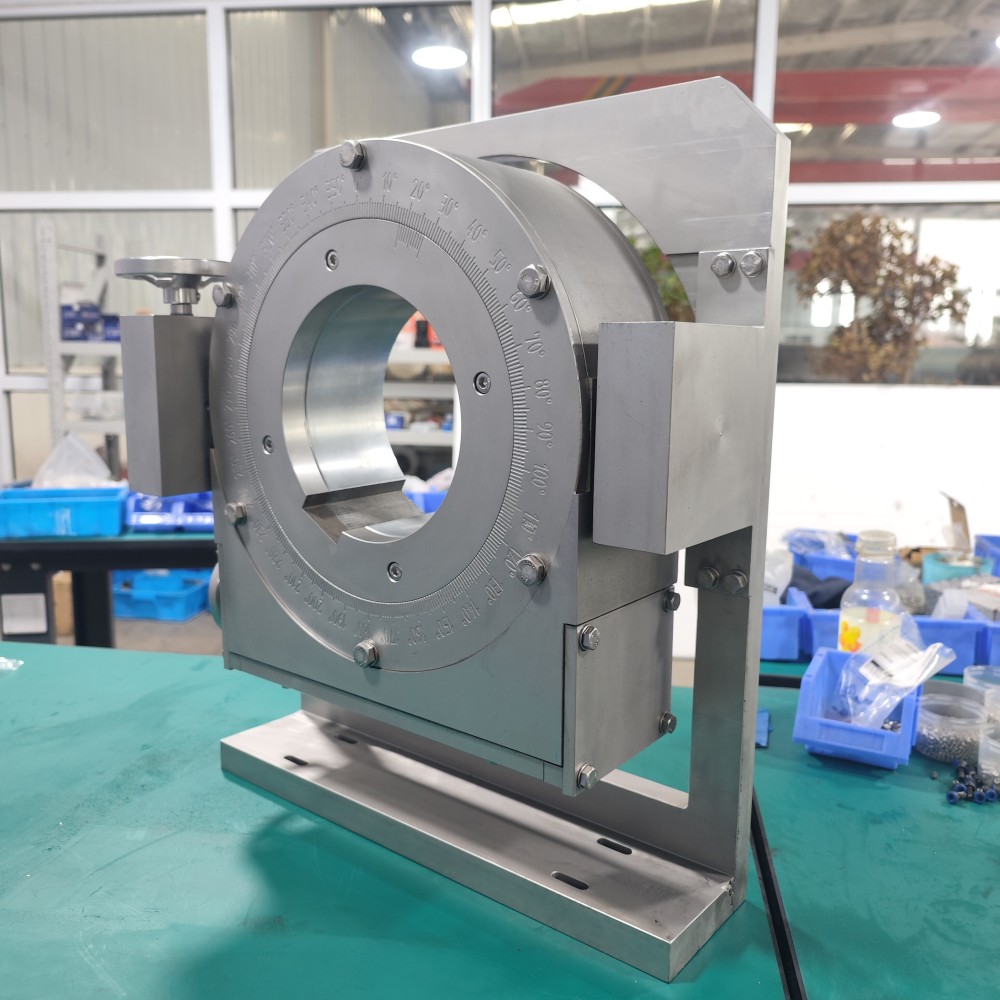

Compact Structure : They occupy minimal space and are suitable for installation inside equipment, especially in scenarios with strict volume requirements.

Smooth Operation : They operate quietly, making them ideal for equipment requiring silent operation.

Application Scenarios

Non-standard worm gear speed reducers are widely used in various scenarios requiring precise transmission and high load capacity, including:

Industrial Automation Equipment : Such as conveyor systems, assembly lines, and packaging machinery, providing stable power transmission.

Smart Home Devices : Such as electric curtains and smart clothes racks, leveraging their compact structure and low-noise characteristics.

Robots and Robotic Arms : They are ideal for precision positioning and load-bearing applications, serving as joints and end-effectors.

Lifting Devices : Relying on their self-locking function, they are widely used in hoisting and lifting machinery.